The paper and pulp industry needs robust machinery that can keep up with high-volume production while withstanding the chemicals used in paper processing. Different types of stainless steel grades and nickel-containing alloys have the properties to provide long-lasting durability, superior mechanical characteristics, and chemical resistance for reliable, smooth operations.

As a high-quality metal fabrication service provider, Industrie Lemieux creates cost-effective, process-proof metal fabricated equipment, including pipes, structural supports, tanks, and other machine hardware. Learn more about the benefits of our metal design and fabrication capabilities and their applications in the paper and pulp industry.

Metal Design and Fabrication in the Pulp and Paper Industry

Manufacturers in the pulp and paper industry primarily use stainless steel equipment to process pulp and refine it into paper products. Compared to most other metals, stainless steel offers the right combination of corrosion resistance, strength, cost-effectiveness, and machinability. Stainless steel components can withstand constant exposure to process liquors throughout their long service life.

304 and 316 stainless steel are the most common types, but more pulp and paper factories are starting to turn to duplex stainless steel because it offers better performance for its price.

Key advantages of choosing high-quality stainless steel alloys for pulp and paper machinery in this industry include:

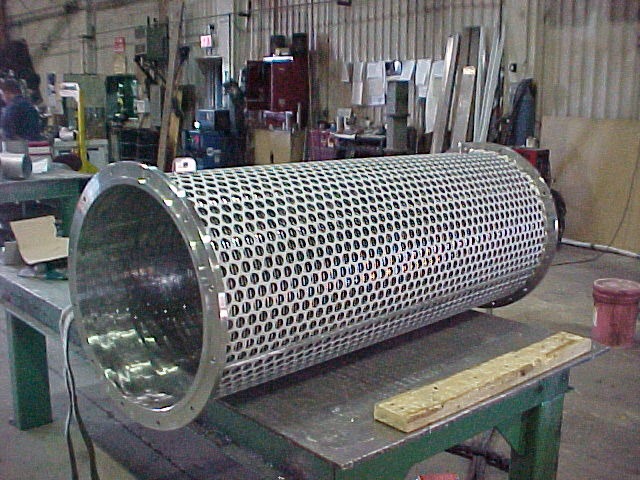

- Versatility. Stainless steel alloys are versatile and easy to work with via techniques like bending, cutting, machining, and welding. Metal fabricators use stainless steel stock material to manufacture parts for digesters, dryers, refiners, and stock chests.

- Chemical resistance. Stainless steel can tolerate repeated cycles of exposure to process liquors, harsh chemicals, and a wide variety of abrasive paper and pulp production processes.

- Better operational lifespan. Stainless steel performs predictably well over time and requires less maintenance, ensuring smoother operations and lower costs over time.

Metal Fabrication Applications in the Pulp and Paper Industry

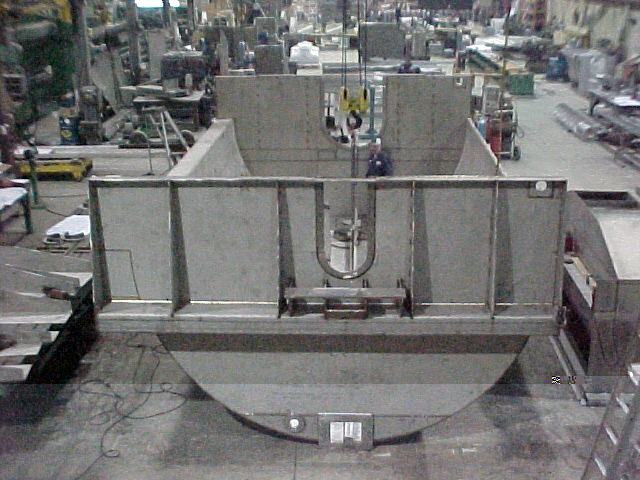

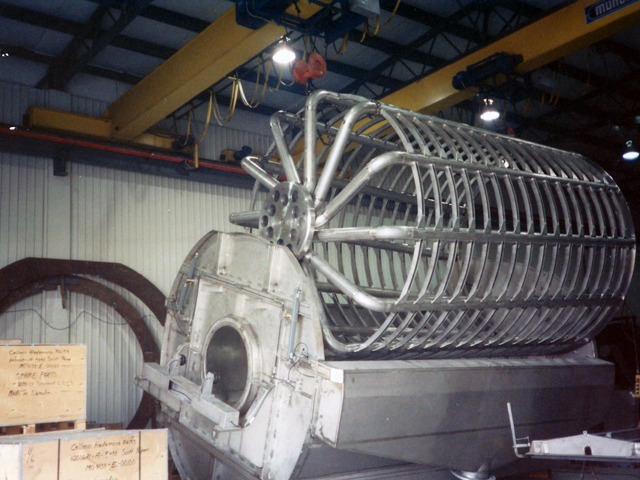

Metal fabricators can create a wide range of specialty components, subassemblies, and containers for use in various pulp and paper equipment. Stainless steels and nickel alloys are popular for creating assemblies like digesters and reactors.

Paper manufacturers typically use either batch cooking or continuous cooking to process pulp. Batch cooking facilities use multiple small batch digesters, while continuous cooking uses one or two larger units. Over the years, both types of digesters have moved from carbon steel to austenitic and duplex stainless steel construction.

Oxygen delignification and broken stock washing units also rely on specialty stainless steels. If constructed with Type 316L stainless steel, some reactors respond poorly to chloride and develop chloride stress corrosion cracking. Today, expert metal fabricators use duplex stainless steel grades to create longer-lasting reactors.

Why Choose Industrie Lemieux?

Choosing the right materials and grades of steel for pulp and paper machinery can significantly affect productivity, uptime, and reliability. Thus, it’s important to work with the right metal fabrication partner who can recommend and source the right types of steel, design and fabricate highly precise components, and back your equipment with technical support as needed for long-term functionality.

At Industrie Lemieux, we’re committed to innovative, high-quality metal fabrication. Each piece of equipment we build meets or exceeds high standards for physical and mechanical strength, so it can withstand high-volume applications. Our solutions are engineered with special finishes and features to thrive long-term in any production environment.

Industrie Lemieux is a leading provider of process-proof equipment for the paper and pulp industry. Our clients can trust our products and assemblies to withstand harsh chemicals and processing liquors. We offer tailor-made, competitively priced solutions for processing systems of any size and scope.

Pulp and Paper Machinery From Industrie Lemieux

Choose the stainless steel fabrication experts with years of experience creating equipment for pulp and paper production and other sectors. Industrie Lemieux specializes in metal fabrication for high-performance tanks, piping elements, vessels, structural components, and more. We carefully select and fabricate materials that offer superior corrosion resistance and resilience for high-stress industrial conditions.

Contact us today to discuss your pulp and paper equipment needs, or request a quote to start your solution.

Some of our achievements

Do you have any questions or comments?